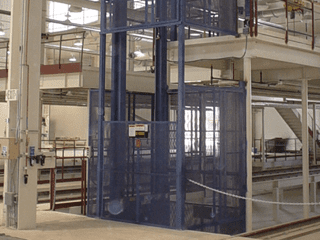

Autoquip’s Freightlite® Optimizes Inventory, Handling, and Storage

The industry standard in vertical lifts, the Freightlite vertical reciprocating conveyors (VRCs) support the lift carriage and load from beneath throughout the vertical travel of the lift. Freightlite® lifts travel up to 183″ with capacities of 3,000 lbs. Hydraulic VRCs are often used for material transfer between landings, mezzanine access, and conveyor systems, which improves the use of vertical building space, enhances stability and safety during load transfer and increases manufacturing efficiency.

Durability and Quality

- High-capacity needle-bearing rollers produce smooth, reliable carriage movement.

- High-impact rubber carriage stops absorbing the shock and noise of the carriage as it stops at the upper landing.

- All hydraulic lifting rams naturally self-align to minimize side loading and wear on the bearings and seals.

- Lifting ram stabilizer arms eliminate ram deflection and side loading of the ram seals, extending the life of the rams and seals.

- Minimum ¼ inch thick steel reinforced platform minimizes deck deflection, maximizes load stability, and extends the life of the platform deck.

- Structural steel guide beams ensure consistent, reliable tracking of carriage rollers and extend the life of the beams

- Chrome plating improves the durability of the rods and extends the life of the cylinders and the seals.

Simplicity

- Each hydraulic VRC ships fully assembled, including chains and cables.

- Upper landing carriage stops are easily adjustable over a 3-inch stopping distance.

- Freightlite® carriage requires no overhead structure and enables an unlimited load height.

- Cantilevered design permits 3-way carriage loading.

Safety

- Automatic re-pressurization of the hydraulic system keeps the carriage level with the upper landing, which is critical when the lift is idle for long periods.

- Physical stops at the upper landing prevent the carriage from moving during the loading and unloading of the lift.

- Standard-issue shaft way barrier bar system improves personnel safety when the carriage leaves the upper landing.

- Interlocked landing gates automatically lock once the vertical lift carriage leaves a landing and cannot be opened until the lift carriage returns to that landing.

- Gate status switches prevent lift operation while any gate is open.

- Hydraulic velocity fuses completely stop lifts in the unlikely event of uncontrolled descent due to sudden hose rupture.

- The minimum 3:1 structural factor of safety makes these lifts the most structurally sound in the industry.

- Compliance with recognized standards:

- ASME B20.1 – Safety Requirements for Conveyors and Related Equipment

- VRC Application Guidelines – as referenced by ASME B20.

- NFPA 70 – National Electric Code

- ASTM-A36 – Structural Steel Standard

- ANSI Z535 – Safety Labeling Requirements

- AWS D.1 – Welding Standards

- Applicable portions of OSHA 29CFR1910 – General Workplace Safety

Maintenance and Warranty

- Maintenance-free carriage rollers require no lubrication.

- A One-piece, structural steel maintenance device safely supports the lift carriage during an inspection and routine maintenance.

- A sturdy, semi-transparent polyurethane oil reservoir provides an easily visible method of checking fluid levels and eliminates oil contamination due to rust.

- Double wire braided Parker hydraulic hoses resist wear, abrasion, and leaks

- Autoquip offers a 1-year warranty on all parts and a 5-year warranty on the lift structure as a promise that you’ve purchased the industry’s most reliable VRC.