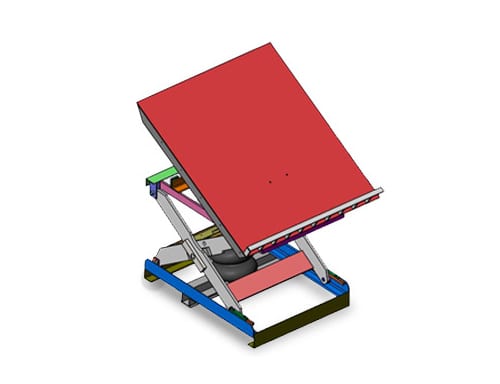

Air-Powered Lift & Tilt Table

Simple to operate and easy to maintain. Heavy industrial pneumatic airbag actuators drive Air Force Lift and Tilt Tables. They are ideal for cleanroom applications because they are not susceptible to oil leaks or spills associated with hydraulic units. Operators can adjust loads vertically and in a degree of tilt to keep items within reach as loading or unloading occurs. This reduces exposure to back injury by keeping the work in the operator’s ergonomic “power zone,” which improves employee productivity and greater work quality.

Durability and Quality

- Built-in Air Damper reduces “bounce” inherent in most pneumatic tilters as the platform lowers under load.

- Joints, the most critical wear points in the lift, feature chrome-plated, 100,000 psi, ultimate-strength pins for premium load strength and long life.

- Solid steel legs and added stiffeners provide stability and straight, repeatable roller tracking as the lift raises and lowers.

- A minimum 1/4-inch-thick steel-reinforced platform minimizes deck deflection, maximizes load stability, and greatly extends the life of the platform deck.

- Structural steel support in upper and lower frames provides additional rigidity and resistance to twisting/bending of the tilter under load.

Simplicity

- Built-in fork truck pockets allow for easy relocation and sharing between workstations.

- Connect the shop air supply using the quick-disconnect air fitting to begin using.

- The exceptionally low lowered height allows for greater on and off-load flexibility and increases total ergonomic range.

Safety

- Fixed flow control, mounted directly to the air actuator, controls the descent of the tilter platform in the unlikely event of a sudden hose or airbag rupture.

- Base rollers are captured for improved load stability and operator safety.

- The minimum 3:1 structural factor of safety makes these lifts the most structurally sound in the industry.

- Compliance with recognized standards:

- ANSI MH29.2 – Safety Requirements for Industrial Tilters

- ANSI MH29.1 – Safety Requirements for Industrial Scissor Lifts

- NFPA 70 – National Electric Code

- ASTM-A36 – Structural Steel Standard

- ANSI Z535 – Safety Labeling Requirements

- AWS D.1 – Welding Standards

- Applicable portions of OSHA 29CFR1910 – General Workplace Safety

Maintenance and Warranty

- Autoquip offers an industry-best 2-year warranty on all parts as a promise that you’ve purchased the industry’s most reliable tilter.

- Maintenance-free bearings at pivot points require no lubrication.

- On-board maintenance devices enable maintenance crews to safely and effectively block open the tilter during an inspection and routine maintenance.

- A sturdy, semi-transparent polyurethane oil reservoir provides an easily visible method of checking fluid levels and eliminates oil contamination due to rust.

- Double-wire braided Parker hydraulic hoses resist wear, abrasion, and leaks.